PRODUCT SPECIFICATION

Steel Types

MILD STEELKhansforge utilizes a high quality killed steel for load bearing bars, which exceeds the strength of BS, EN10-025 Fe430A (BS 4360 Grade 43A). This is particularly beneficial where a floor is subjected to wheel loads, as deflection becomes a subordinate consideration to the ability of the load bearing bar to withstand high stress. If required, other grades of steel are available, such as ASTM A36, JIS G3101 SS 400, AS3679 Grade 250, or other equivalent specifications.

STAINLESS STEELKhansgrate can be manufactured from stainless steel. The normal grades used are 304 and 316, but other grades can be considered upon request.

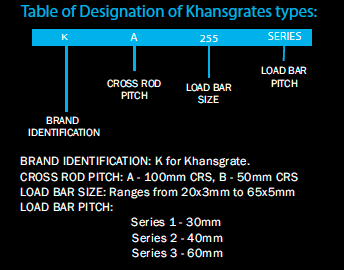

DESIGNATIONEach Khansgrate type is coded for an easy identification as shown in the following example:

Click on image for a larger view

|

PLAINIn its standard form Khansgrate is supplied with plain load bearing bars and 6mm square twisted cross rods.

SERRATEDSerrated grating is available with most standard load bearing bars. The serrations are formed by placing a series of notches along the upper edge of the load bar, thus enhancing the non- slip characteristics of the grating. When serrated grating is required it must be nominated (eg. KA325 series 1 serrated).

|

KHANSGRATE I-BAR (PLAIN)In its standard form Khansgrate is supplied with plain i-bar and 6mm square twisted cross rods.

KHANSGRATE I-BAR (SERRATED)Serrated i-bar grating is available with most standard load bearing bars. The serrations are formed by placing a series of notches along the upper edge of the load bar, thus enhancing the non- slip characteristics of the grating. When serrated grating is required it must be nominated (eg. KAI325 series 1 serrated).

|

Availability

Khansgrate is available in standard panel form, normally from stock, in panels generally 6 metres long x normally 1 metre wide. Load bearing bars of 55 x 5mm and 65 x 5mm are normally supplied in 4.0 metre lengths. Other lengths are available upon request. Alternatively, Khansgrate can be fabricated to any shape and size to meet customers requirements.

Treatment

Khansgrate is available with the following finishes:

1) UNTREATED - no rust protection, thus allowing quicker deliveries to those who fabricate their own flooring.

2) DIPPED BLACK BITUMEN - a most economical paint finish where the grating is dipped in a tank of bitumen based paint. There is no pre-treatment of the steel before dipping. This coating is most suited for indoor and dry conditions.

3) RED OXIDE - This is basically used as a primer coat when additional paint finishes are required.

4) GALVANIZED - This finish ensures that the entire surface area is protected by a uniform layer of zinc and therefore is suitable for the majority of applications. Hot dip galvanizing conforms to the following equivalent standards AS/NZS 4680, EN ISO1460. 1999, ASTM 123. The minimum average coating required by these standards is610g/sq metre.

5) STAINLESS STEEL - When stainless steel Khansgrate is specified, it should be noted that floor panels will be supplied with a standard pickled finished. In addition to this, an electropolished finish is also available.

2) DIPPED BLACK BITUMEN - a most economical paint finish where the grating is dipped in a tank of bitumen based paint. There is no pre-treatment of the steel before dipping. This coating is most suited for indoor and dry conditions.

3) RED OXIDE - This is basically used as a primer coat when additional paint finishes are required.

4) GALVANIZED - This finish ensures that the entire surface area is protected by a uniform layer of zinc and therefore is suitable for the majority of applications. Hot dip galvanizing conforms to the following equivalent standards AS/NZS 4680, EN ISO1460. 1999, ASTM 123. The minimum average coating required by these standards is610g/sq metre.

5) STAINLESS STEEL - When stainless steel Khansgrate is specified, it should be noted that floor panels will be supplied with a standard pickled finished. In addition to this, an electropolished finish is also available.